In manufacturing, precision and efficiency go hand in hand. Ensuring a strong and long-lasting connection is critical for fasteners such as screws. Thread forming plays a vital role in achieving this, as it enables the fastener to grip securely into the receiving material. This is where High Speed Steel (HSS) self-drilling screw rolling dies come into play, revolutionizing the industry with their superior capabilities.

The innovation of the self-drilling screw rolling die is that it can combine the two processes of drilling and tapping into one. Traditionally, these processes have been performed individually, which not only consumes additional time, but also increases the risk of misalignment. With hss self-drill screw thread rolling dies, manufacturers can now optimize production efficiency without compromising quality.

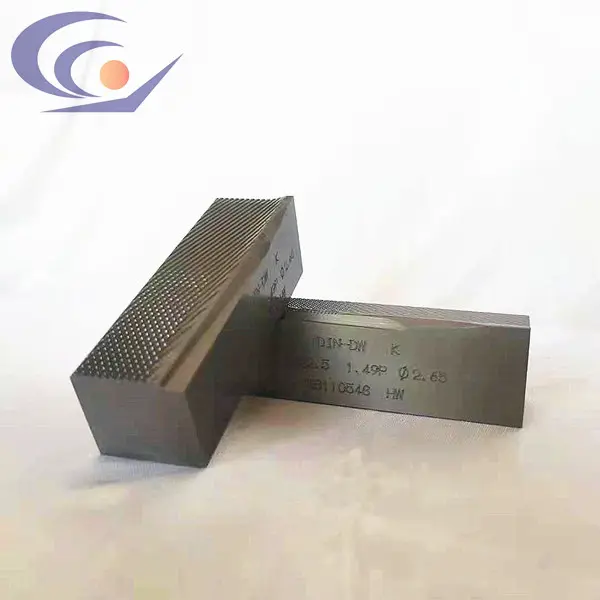

One of the most significant advantages of using HSS self-drilling thread rolling dies is their high-speed capability. As the name suggests, HSS is known for its exceptional speed and durability. The mold is made of high-quality high-speed steel, which has excellent properties such as high wear resistance and high hardness. This ensures that the mold can be used at higher speeds without compromising its overall performance. result? Significantly reduce production time, thereby increasing output and reducing costs.

Additionally, the self-drilling capability further simplifies the manufacturing process by eliminating the need for pre-drilled or pre-tapped holes. High speed steel self-drilling thread rolling dies produce precise threads while self-drilling through the material. Not only does this save time, it also eliminates the risk of misalignment and ensures that the threads are perfectly formed for a safe and secure connection.

In addition, HSS self-drilling screw rolling dies can accommodate different thread sizes, providing versatility. Whether coarse or fine pitch, dies can be easily adjusted to meet the specific requirements of a project. By providing this flexibility, manufacturers can rely on a single tool for a variety of fastening applications, reducing the need for multiple molds or tooling.

In addition to efficiency and versatility, HSS self-drilling thread rolling dies also contribute to sustainable manufacturing practices. By eliminating the need for separate drilling and tapping operations, energy consumption is reduced, thereby reducing carbon emissions. Additionally, the service life and durability of HSS tooling means less waste and fewer replacements, promoting an environmentally friendly approach to the production process.

In conclusion, high speed steel self-drilling thread rolling die embodies the efficiency, precision and durability of the fastener industry. By combining drilling and threading into a single operation, manufacturers can significantly increase productivity while ensuring the highest quality thread formation. With its high-speed capability, versatility and contribution to sustainable development, this innovative tool is revolutionizing the way fasteners are manufactured around the world. Increase your production capacity, save time and money, and achieve reliable thread forming with superior HSS self-drilling thread rolling dies.

Post time: Aug-11-2023